Titanium Machining and the Factors to Consider for Production

Titanium contains a mixture of titanium and other chemical elements. These alloys have very high tensile strength and toughness—even at extreme temperatures. They are light in weight, have extraordinary corrosion resistance, and the ability to withstand extreme temperatures. Use is primarily limited to industrial applications for military, aircraft, spacecraft, high technology and medical devices.

Although “commercially pure,” titanium has acceptable mechanical properties and has been used for orthopedic and dental implants; for most applications, titanium is alloyed with small amounts of aluminum and vanadium, typically 6% and 4% respectively, by weight. This mixture has a solid solubility (allowing it to dissolve in a solid, liquid, or gaseous solvent), which varies dramatically with temperature, allowing it to undergo precipitation strengthening. This metallurgic heat treatment process is carried out after the alloy has been worked into its final shape but before it is put to use, allowing much easier fabrication of a high-strength product.

Factors to Consider for Producing Precision Machined Titanium Parts

This webpage provides you the full scope about machining titanium and the questions—and answers—commonly asked about its use for parts and components from a precision machining perspective. Read the entire discussion or jump to the section that interests you by clicking on the links below.

Precision Titanium Machining Challenges

While titanium’s strength and toughness make it the ideal choice for use in extreme environments, it also poses major challenges for those machining it. While titanium is fairly stable, it generally holds up well to tight tolerance and location callouts.

Factors that influence titanium’s machinability are:

- Poor conduction of heat, effectively concentrating the heat on the cutting edge and tool face, creating excessive wear

- Chemical reactivity, which causes galling, welding, and smearing, all also leading to compromising the cutting process

- Precise speeds and feeds required to mitigate titanium’s “hard and tough” quality that tends to lead to long cycle times per part

- Part designs with tight corner radius/fillet callouts

Solving Part Issues When Machining Titanium

These tooling challenges can also lead to challenges with parts. As an example, this can cause galling—and tools with sharper corners, such as taps or boring bars, will:

- Produce part-to-part inconsistencies

- Create calibration and tolerance issues

- Affect quality

- Slow down production, ultimately

To avoid this, each part requires careful process planning. By making modifications and creating a proprietary process, Specialized Turning has become an expert at machining titanium and is able to create a more consistent and high-quality part for the customer.

Titanium Machining Costs

The high amount of energy required to separate titanium is one of a few primary factors of the high price of machining this tough metal. Once on the tooling floor, machining is costly. When machining titanium, we must consider some tough restrictions on machining parameters that can affect:

- Metal removal rates

- Surface finish quality

- Dimensional accuracy

- Tool life (premature tool change vs. expense of regrind)

- Run time (as compared to machining other types of alloys)

- General maintenance of machines

Titanium Machining Tooling

Understanding tool limitations is crucial to prevent failures when machining titanium. Preventing work hardening, which occurs when the metal ahead of the cutting tool becomes plastically deformed, is the key to success. This requires advanced planning as well as a thorough understanding of the limitations of the various tooling being used.

The average tool life varies by tool and a plan needs to be in place to remove and replace the tool as the part is worked. This must be done in consideration of the various operations required to produce the finished part. It is often considered impractical to stop and change a tool in the middle of an operation without negatively affecting the quality of the finished piece. In practice, however, there are times when this must be done, and the titanium machine shop will need to engineer this strategy in advance of the machining process. In summary, each cutting tool should have a planned replacement cycle of use and then be re-sharpened or discarded.

Types & Attributes of Titanium Grade 2

Commercially pure Grade 2 titanium is used in a variety of applications and is widely available in many forms. It has high-impact toughness and corrosion resistance. This grade possesses good weldability, strength, ductility, and formability. Grade 2 titanium bar and sheet are the prime choice for many fields of applications, including power generation, medical industry, hydro-carbon processing marine industry applications, and chemical processing.

Grade 7

Grade 7 is an alloyed grade and is mechanically and physically equivalent to Grade 2, except with the addition of palladium, making it an alloy. Grade 7 possesses excellent weldability and fabrication qualities, and is the most corrosion resistance of all titanium alloys. In fact, it is most resistant to corrosion in reducing acids. Grade 7 is used in chemical processes and production equipment components.

Ti 6Al-4V (Grade 5)

The most popular of the titanium alloys is Ti 6Al-4V, or Grade 5 titanium. It accounts for 50% of total titanium usage the world over. Ti 6Al-4V may be heat treated to increase its strength and can be used in welded assemblies at service temperatures of up to 600° F. This alloy offers its high strength at a light weight, useful formability, and high corrosion resistance. Ti 6AI-4V’s usability makes it the best alloy for use in several industries, including aerospace, medical, marine, and chemical processing industries.

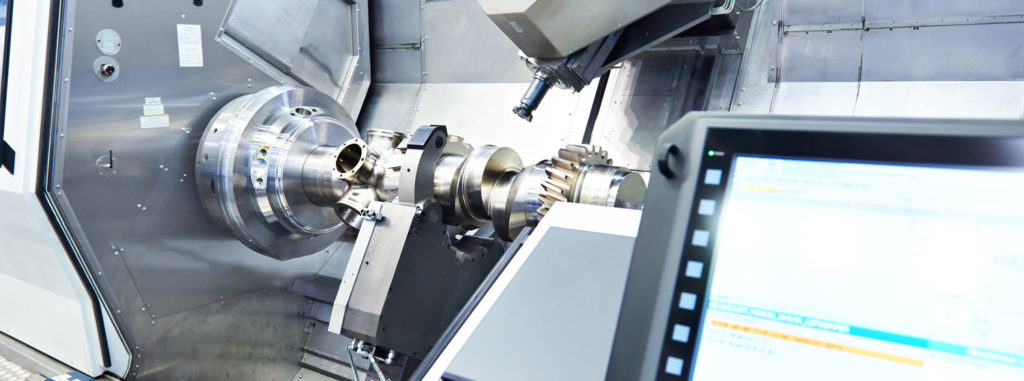

Decades of Experience at Work for You

At Specialized Turning, we are experts in machining titanium alloys to produce the best possible quality and value. While each type of titanium has its own intricacies, we match state-of-the-art tooling geometries and coatings to ensure the most economical stock removal rates at the highest speeds possible for economical machining. Our staff has decades of experience in:

- Custom machining titanium

- Titanium turning

- Precision titanium machining

- Titanium milling

- CNC machining titanium

Our extensive inventory of tooling allows us to minimize expenses for upfront costs and order processing.

Let’s talk about your titanium needs. We’d love to get the conversation started.